Insertion-type electromagnetic flowmeter sensor: An efficient and cost-effective choice for large-diameter flow measurement

Category: Blog

Published time: 2025-07-11

Summary:

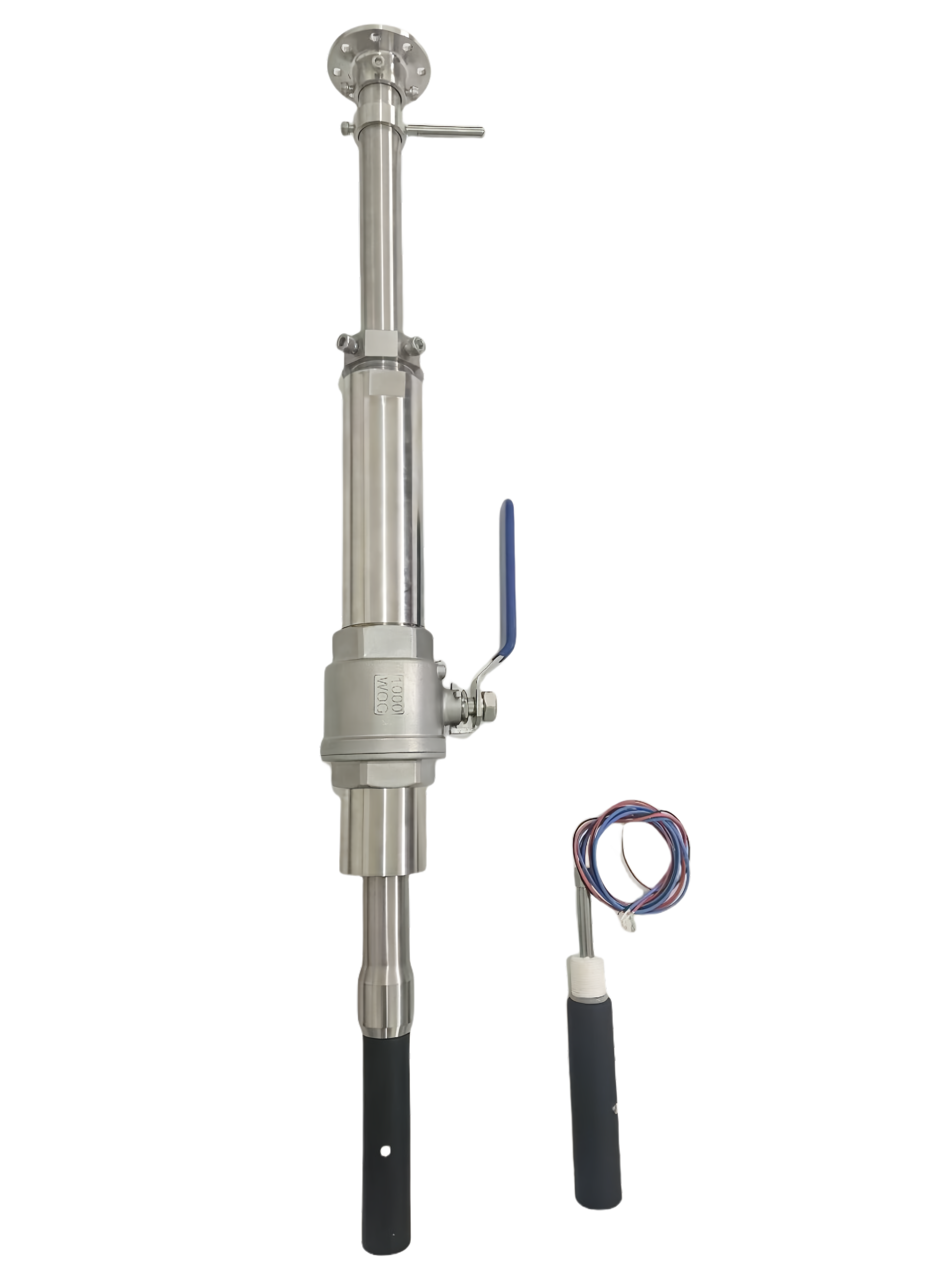

In large-scale pipeline systems used in industrial water treatment, municipal networks, energy metering, and other fields, the installation of conventional segment-type electromagnetic flowmeters often faces challenges such as high engineering effort, elevated costs, and prolonged production downtime. Insertion-type electromagnetic flowmeter sensor With its unique design concept, it has become the preferred solution for tackling the challenging task of flow measurement in large-diameter pipelines (DN100–DN3000).

Core Advantages and Feature Analysis:

304 Stainless Steel Housing: Robust and Durable Industrial-Grade Protection

Outstanding Environmental Adaptability: The sensor housing is made of Premium 304 Stainless Steel , featuring outstanding mechanical strength and superior corrosion resistance. It effectively withstands moisture, chemical corrosion, and physical impacts, ensuring the instrument operates reliably and stably over the long term in challenging industrial environments such as wastewater treatment plants and industrial circulating water systems.

Long-term Reliability Assurance: The robust housing provides a solid barrier for the delicate electromagnetic induction components and electrical connections inside, reducing the risk of external environmental interference and accidental damage, thereby ensuring the continuous reliability of measurement data.

Installation Revolution: Convenient and Efficient, Far Outperforming Pipe-Section Models

Installation under pressure, no need for production shutdown (key advantage): The product is specifically designed for Installation under pressure Design. No need to cut the pipeline, drain the fluid, or shut down the system for an extended period—installation can be done directly in the pipeline. Low-pressure or pressurized operating condition Next, safely and quickly complete the installation or removal of the sensor using dedicated mounting tools (such as a drilling kit). Compared to segmental electromagnetic flowmeters that require pipe cutting, flange welding, and prolonged production shutdowns, this is a revolutionary convenience.

Engineering costs significantly reduced: It eliminates the costly and complex processes required for spool-piece installation, such as cutting pipes, welding flanges, and prolonged system downtime. Installation time is significantly reduced, and labor costs are lower—especially beneficial for large-diameter pipes (DN500 and above), where cost savings become even more pronounced. Extremely remarkable 。

Easy maintenance: Instrument maintenance, probe replacement, or calibration has become exceptionally simple—no need for extensive pipeline disassembly, significantly boosting operational efficiency while reducing maintenance costs.

Structurally stable, measurement reliable

Design with no moving parts: Sensor There are no moving parts inside. (All models emphasize this point.) Fundamentally eliminates potential failures such as mechanical wear and jamming, ensuring extremely reliable operation, minimal maintenance requirements, and an exceptionally long service life.

Optimize the structure to enhance performance: As used in the CLD-6034 model Dual Excitation Structure , effectively enhancing signal stability, improving resistance to fluid disturbances and electromagnetic interference, and ensuring measurement consistency even under complex operating conditions.

Reliable precision: Provide ±1.5% The accuracy class (meeting product specifications) satisfies the precision requirements for large-diameter flow measurements in most process monitoring and trade settlement applications, such as water utility metering.

The ideal choice for large-caliber applications

Ultra-wide aperture coverage: The CLD-6034 model is specifically designed for large and medium-sized pipelines ranging from DN100 to DN3000. , perfectly suited for common scenarios in water utilities, municipal projects, and large industrial facilities—such as main water transmission pipelines and raw/wastewater trunk lines. Its design effectively addresses the measurement challenges posed by exceptionally large pipe diameters (e.g., flow velocity distribution).

Probe is sturdy and reliable: The CLD-6034 probe utilizes Single-use injection molding Craftsmanship ensures exceptional performance. Overall structural strength and sealing performance , preventing medium leakage, especially suitable for large-diameter pipelines in long-term operation.

Reasonable insertion depth: CLD-6034 scientifically sets the insertion depth according to pipe diameter (1/2 D for DN400 and smaller, and 1/4 D for DN450 and larger), ensuring that the measurement point is located in a representative flow velocity region to guarantee measurement accuracy.

Small caliber performs just as well: The CLD-8028 model covers pipes with a diameter of DN50 and above, and the probe has a minimum outer diameter of just 28mm , highly adaptable.

Flexibly configured to adapt to diverse media

Enrich electrode materials: Offering a variety of options including 316L stainless steel, Hastelloy (HC), titanium (Ti), tantalum (Ta), platinum-iridium alloy, and more—easily meeting the measurement needs for conductive liquids such as clean water, wastewater, and corrosive chemical solutions.

Reliable probe material: CLD-6034 utilizes Engineering plastics , the CLD-8028 features high performance PEEK (Polyether Ether Ketone) PEEK offers superior high-temperature resistance (up to ≤80℃) and chemical corrosion resistance, making it suitable for a wider range of operating conditions.

Media temperature adaptability: CLD-6034 is suitable for media up to 60°C, while CLD-8028 is designed for media up to 80°C.

Why choose an insertion-type solution over a segmental one for large-diameter pipelines?

Installation convenience takes the lead: Pressurized installation vs. pipe-cutting, production-halt installation.

Initial costs significantly reduced: Eliminate the costs of pipe cutting, flange welding, and extra pipe sections—especially for sizes above DN500, where the cost advantage is significant.

The project cycle is extremely short: Hours vs. days—or even weeks.

Lower maintenance costs: The maintenance does not require extensive pipeline work.

Lower requirements for operating conditions: The requirements for straight pipe sections are typically lower than those for segmental pipes, offering greater installation flexibility.

Especially suitable for renovation projects: Installing a flowmeter on an already operational, ultra-large pipeline—insertion-type—is virtually the only economically viable solution.

Typical application scenarios:

Municipal Water Services: Water plant raw water/outgoing water main-line metering, district water supply network monitoring (DMA), inflow/outflow flow monitoring at large wastewater treatment plants, and reservoir intake canals.

Industrial Recirculating Water: Monitoring of total cooling water pipelines and mainline flow in circulating water systems at large-scale plants (power plants, chemical plants, steel mills).

Energy Industry: Measurement of hot/cold water flow and heat/cold energy in the district heating/cooling trunk network.

Hydraulic Engineering: Monitoring of water flow at large-scale irrigation channels and pump station outlets.

Others: Centralized chilled and hot water main pipe metering for large building complexes.

By choosing our insertion-type electromagnetic flowmeter sensor, you will receive:

Durable and robust: 304 stainless steel housing, industrial-grade protection.

Installation Revolution: Installation under pressure saves time, effort, and money—especially ideal for large-diameter applications.

Stable and reliable: No moving parts, dual excitation design, ±1.5% accuracy.

Large-caliber expert: DN100-DN3000 provides perfect coverage, with engineering plastic/PEEK probes offering reliable sealing.

Flexible adaptation: Multiple electrode materials are available to meet the needs of different media.

Limited-time blockbuster offer—empowering your major projects!

To help large-scale infrastructure and industrial projects reduce costs and improve efficiency, we are introducing special offers starting today: Enjoy an exclusive 20% discount when you order bulk quantities of plug-in electromagnetic flowmeter sensors (CLD-6034 / CLD-8028)! Whether you're building a new large-scale pipeline network or upgrading an aging system, this is an excellent opportunity to enhance your flow monitoring capabilities and optimize your cost structure.

Consult now to get your personalized plan!

Click the button below or call our expert team: 0374-8098777 , or leave a message to receive detailed product technical specifications, selection recommendations tailored to your plumbing conditions, and highly competitive bulk discount quotes. Let us provide the perfect, efficient, cost-effective, and reliable solution for your large-diameter flow measurement challenges!

Keywords: Insertion-type electromagnetic flowmeter sensor: An efficient and cost-effective choice for large-diameter flow measurement

Related information

Company News

-

Factors to consider when purchasing an intelligent electromagnetic flowmeter

Release time:2025-01-03

-

What type of flow meter is best for measuring flow rate in the petroleum industry?

Release time:2025-05-08

-

Factors to consider when purchasing a smart electromagnetic flow meter

Release time:2025-04-08

-

What type of flow meter is best suited for measuring flow rate in the petroleum industry?

Release time:2025-04-08

-

The explosion-proof performance of various instruments is extremely important in the chemical production process!

Release time:2025-04-08

Industry News

-

Precise Measurement, Smart Choice: A Comprehensive Analysis of Zhongce Sensing's Pipeline-Type Intelligent Electromagnetic Flowmeter

Release time:2025-09-23

-

Zhongce Sensing Filling Electromagnetic Flowmeter: The Core Tool for Precise Measurement

Release time:2025-09-20

-

Analysis and Application Practices of Insertion Electromagnetic Flowmeters

Release time:2025-09-17

-

Technical Analysis of Slurry-Type Electromagnetic Flowmeters

Release time:2025-09-17

-

Precision measurement, replacing imports: Newly launched filling electromagnetic flowmeters empower the beverage and pharmaceutical industries.

Release time:2025-09-12

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: Parameter, Installation, and Selection Guide

Release time:2025-08-05

-

Zhongce Sensing Electromagnetic Water Meter: The Pioneer of Precise Measurement in the Era of Smart Water Management

Release time:2025-08-05

-

Zhongce Sensing Pipeline Electromagnetic Flowmeter: Precise Measurement, the Reliable Choice for Fluid Flow Applications

Release time:2025-07-29

-

Micro and Miniature Electromagnetic Flow Meters: Small Size, Big Impact—Precision Measurement Empowers High-Precision Industries

Release time:2025-07-24

-

Zhongce Sensing's Miniature Electromagnetic Flowmeter: A Highly Efficient and Precise Choice for Measuring Small Flows

Release time:2025-07-19

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: A Highly Efficient and Convenient Solution for Fluid Measurement

Release time:2025-07-19

-

Henan Zhongce Sensor Electromagnetic Water Meter | IP68 Waterproof + Wireless Remote Transmission—Your First Choice for Smart Water Management and Precise Measurement

Release time:2025-07-16

-

Henan Zhongce Sensor Pipeline Electromagnetic Flowmeter: The Industrial Choice for High-Precision Fluid Measurement

Release time:2025-07-16

-

Micro and Miniature Electromagnetic Flow Meters: The Ideal Tool for Precisely Measuring Tiny Flow Rates

Release time:2025-07-14

-

What are the maintenance methods for electromagnetic flow meters?

Release time:2025-05-08

-

Difference between electromagnetic water meters and electromagnetic flow meters

Release time:2025-05-08

-

Advantages of electromagnetic flow meters

Release time:2025-05-08

-

Internal structure of a magnetic flow meter

Release time:2025-05-08

-

Electromagnetic flow meter principle

Release time:2025-05-08

-

Troubleshooting common malfunctions of electromagnetic flow meters

Release time:2025-05-08