Zhongce Sensing Insertion Electromagnetic Flowmeter: Parameter, Installation, and Selection Guide

Category: Industry News

Published time: 2025-08-05

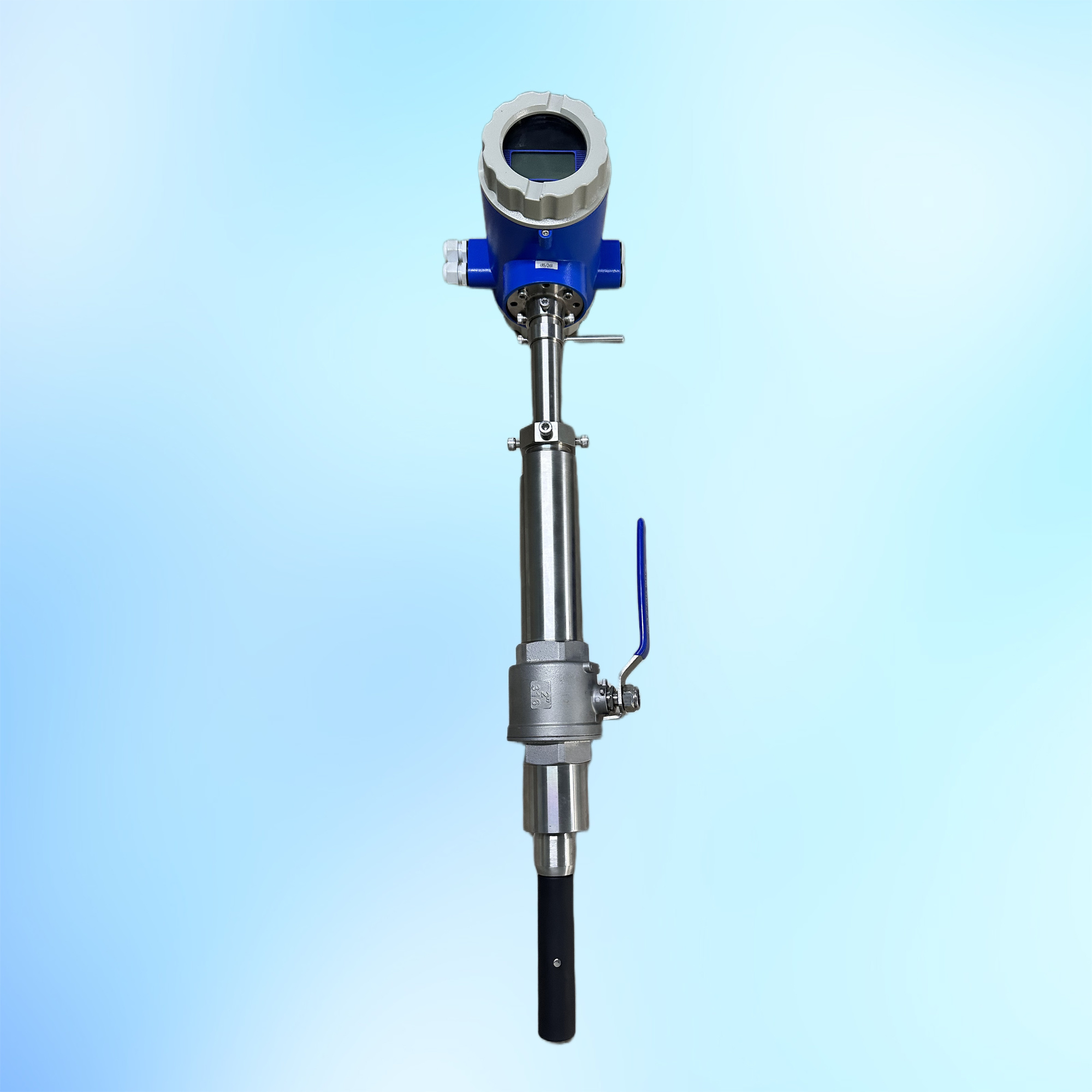

Summary: In the field of industrial flow measurement, traditional flanged instrument installations require shutting down production and cutting into pipelines, resulting in significant economic losses. Henan Zhongce Sensing Technology Co., Ltd. has introduced its insertion-type electromagnetic flowmeter, which stands out with three key advantages: installation under pressure, wide-range adaptability, and easy maintenance—making it the ideal metering solution for DN150 to DN3000 pipelines.

In the field of industrial flow measurement, traditional flanged instrument installations require shutting down production and cutting into pipelines, resulting in significant economic losses. Henan Zhongce Sensing Technology Co., Ltd. has introduced Insertion-type electromagnetic flowmeter With its three core advantages—installation under pressure, wide-range adaptability, and easy maintenance—it has become the ideal metering solution for pipelines ranging from DN150 to DN3000.

I. Why Choose the Insert Type? Solving Three Major Challenges in Industrial Settings

Pain Points of Traditional Instruments :

Production halt losses: The DN1200 pipeline renovation requires a 3-day shutdown, resulting in single-instance losses exceeding one million in the petrochemical industry.

Installation is complex: Large-caliber instrument lifting requires specialized equipment, posing significant safety risks.

Maintenance Challenges: Emptying Chemical Pipelines Triggers Risk of Medium Volatilization

Mid-Test Sensing Solution :

✅ Pressurized hole-opening installation : The ball valve's sealing design allows for installation to be completed in 30 minutes, with a working pressure of 1.6 MPa.

✅ Wide-caliber compatibility : Full-range coverage from DN150 to 3000mm

✅ Dual-electrode structure : Planar electrode design withstands impurity media

II. Core Technology: The Practical Foundation for Precise Measurement

1. Low-frequency square-wave excitation technology

Adopts a 5 μS/cm low-conductivity startup design (Product Feature 2)

Eliminating fluid electrochemical interference boosts zero-point stability by threefold.

The output signal linearity reaches ±0.5% (when the full-scale flow rate exceeds 1 m/s).

2. Graded Installation and Positioning Method

# Pipeline Adaptation Algorithm Pipe diameter DN ≤ 400 mm : Insertion depth = H - 0.121* DN # Central axis measures maximum flow velocity Insertion depth = H - 0.250* DN # Average flow velocity captured at 0.25D

3. Modular Sealing Structure

304 Stainless Steel Compression Threaded Seat + Fluororubber Washer

IP68 protection rating (compliant with GB-08-84 standard)

Operates reliably underwater at 3 meters without leakage.

III. Typical Application Case: A Record of the Tap Water Plant Transformation

Project Background :

The DN800 main water supply pipeline renovation in a certain city must be completed within 72 hours.

Implementation Plan :

Adopting the ZN-CEIF-800 planar electrode type (ABS measuring head)

Install 12 monitoring points with pressure-tapped openings

Configuration with 4–20mA + frequency dual output (see Technical Parameters Section 4.12)

Running Performance :

| Metrics | Before the renovation | After the renovation |

|---|---|---|

| Installation takes time. | Average 8 hours/point | 32 minutes/point |

| Measurement error | ±2.5% | ±0.9% |

| Maintenance Frequency | Quarterly Maintenance | Annual Inspection |

| Data Integrity | 85% | 99.6% |

IV. Selection Guide: Configure Based on Medium Compatibility

Electrode Material Selection

| Medium Type | Recommended electrode | Tolerance characteristics |

|---|---|---|

| Ordinary tap water | Molybdenum-containing stainless steel | Economical and Durable |

| Acidic wastewater | Hastelloy C276 | Acid-resistant to hydrochloric acid |

| Desalination of seawater | Titanium Ti | Chloride-ion corrosion resistance |

Output Signal Configuration

Process control scenario: 4–20mA current output (load resistance 0–500Ω)

Total measurement scenario: 1–5 kHz frequency pulses (250–1.2 kΩ load)

Remote monitoring scenario: RS485 communication (MODBUS protocol)

5. Intelligent Operations & Maintenance: Parameterized Fault Diagnosis

Practical diagnostic approach based on Section 7.3 of the document:

| Fault phenomenon | Quick troubleshooting methods | Solution |

|---|---|---|

| Display negative flow | Check the sensor orientation markings | Rotate 180° and reload |

| The signal fluctuates significantly. | Measure the electrode-to-ground resistance (standard: 10–30 kΩ) | Alcohol-cleaned electrodes |

| No output signal | Test the excitation coil resistance (standard 40Ω) | Replace the sensor |

6. Battery-Powered Solution: A Powerful Tool for Passive Scenarios

3.6V Battery-Type Advantages :

DN800 caliber with a lifespan of 26 months (1/15 Hz excitation)

-20℃ to 50℃ wide temperature range operation

GPRS wireless transmission, with cable-free installation under the manhole cover

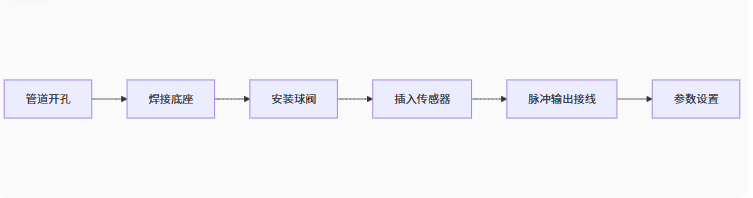

Installation Key Points

Conclusion

Zhongce Sensing Insertion Electromagnetic Flowmeter with "Non-stop production installation, maintenance-free operation" Redefining industrial metrology. When pressurized tapping technology eliminates downtime losses, and modular design reduces maintenance costs, China-made solutions are delivering practical and efficient measurement support to industries worldwide.

Keywords: Zhongce Sensing Insertion Electromagnetic Flowmeter: Parameter, Installation, and Selection Guide

Related information

Company News

-

Factors to consider when purchasing an intelligent electromagnetic flowmeter

Release time:2025-01-03

-

What type of flow meter is best for measuring flow rate in the petroleum industry?

Release time:2025-05-08

-

Factors to consider when purchasing a smart electromagnetic flow meter

Release time:2025-04-08

-

What type of flow meter is best suited for measuring flow rate in the petroleum industry?

Release time:2025-04-08

-

The explosion-proof performance of various instruments is extremely important in the chemical production process!

Release time:2025-04-08

Industry News

-

Precise Measurement, Smart Choice: A Comprehensive Analysis of Zhongce Sensing's Pipeline-Type Intelligent Electromagnetic Flowmeter

Release time:2025-09-23

-

Zhongce Sensing Filling Electromagnetic Flowmeter: The Core Tool for Precise Measurement

Release time:2025-09-20

-

Analysis and Application Practices of Insertion Electromagnetic Flowmeters

Release time:2025-09-17

-

Technical Analysis of Slurry-Type Electromagnetic Flowmeters

Release time:2025-09-17

-

Precision measurement, replacing imports: Newly launched filling electromagnetic flowmeters empower the beverage and pharmaceutical industries.

Release time:2025-09-12

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: Parameter, Installation, and Selection Guide

Release time:2025-08-05

-

Zhongce Sensing Electromagnetic Water Meter: The Pioneer of Precise Measurement in the Era of Smart Water Management

Release time:2025-08-05

-

Zhongce Sensing Pipeline Electromagnetic Flowmeter: Precise Measurement, the Reliable Choice for Fluid Flow Applications

Release time:2025-07-29

-

Micro and Miniature Electromagnetic Flow Meters: Small Size, Big Impact—Precision Measurement Empowers High-Precision Industries

Release time:2025-07-24

-

Zhongce Sensing's Miniature Electromagnetic Flowmeter: A Highly Efficient and Precise Choice for Measuring Small Flows

Release time:2025-07-19

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: A Highly Efficient and Convenient Solution for Fluid Measurement

Release time:2025-07-19

-

Henan Zhongce Sensor Electromagnetic Water Meter | IP68 Waterproof + Wireless Remote Transmission—Your First Choice for Smart Water Management and Precise Measurement

Release time:2025-07-16

-

Henan Zhongce Sensor Pipeline Electromagnetic Flowmeter: The Industrial Choice for High-Precision Fluid Measurement

Release time:2025-07-16

-

Micro and Miniature Electromagnetic Flow Meters: The Ideal Tool for Precisely Measuring Tiny Flow Rates

Release time:2025-07-14

-

What are the maintenance methods for electromagnetic flow meters?

Release time:2025-05-08

-

Difference between electromagnetic water meters and electromagnetic flow meters

Release time:2025-05-08

-

Advantages of electromagnetic flow meters

Release time:2025-05-08

-

Internal structure of a magnetic flow meter

Release time:2025-05-08

-

Electromagnetic flow meter principle

Release time:2025-05-08

-

Troubleshooting common malfunctions of electromagnetic flow meters

Release time:2025-05-08