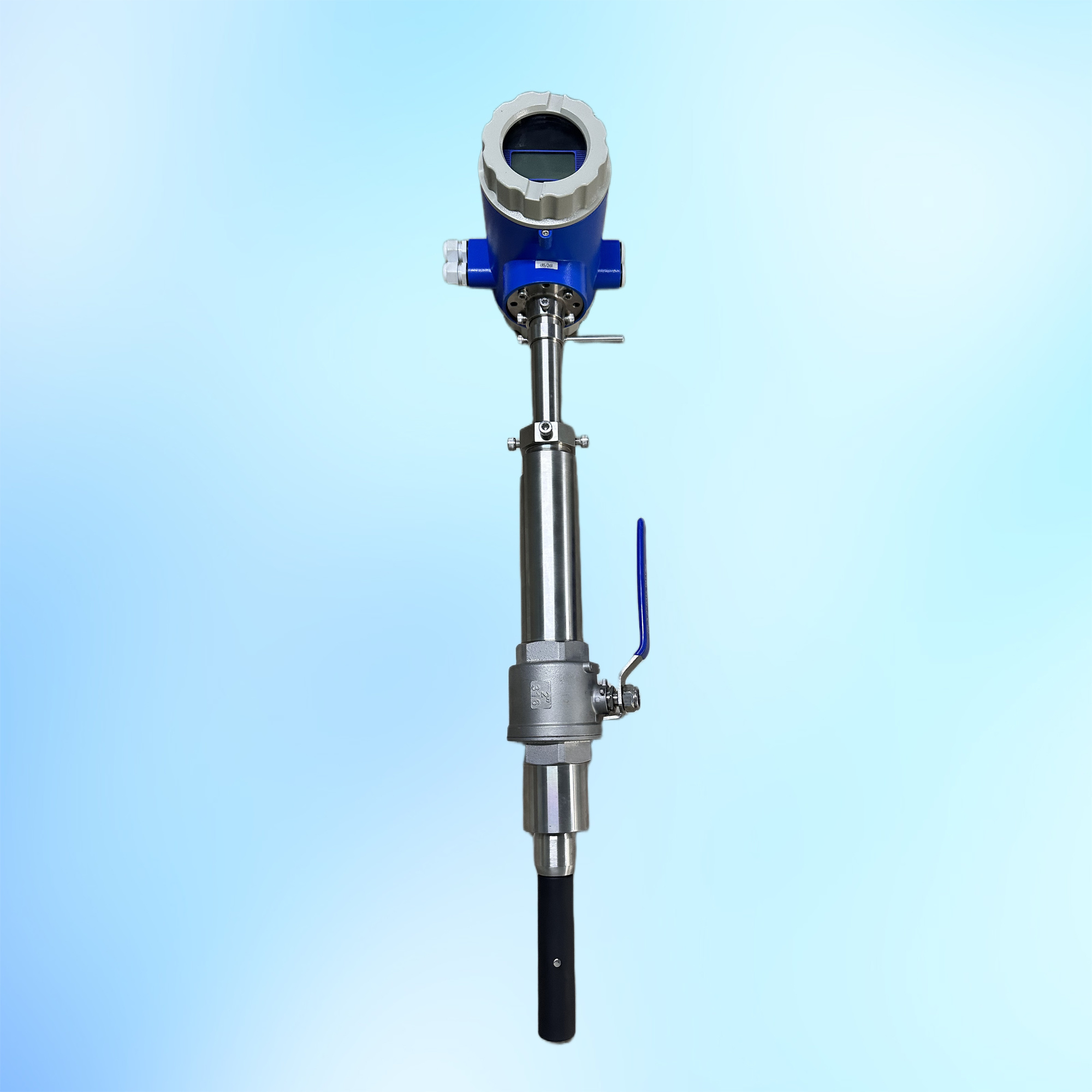

Zhongce Sensing Insertion Electromagnetic Flowmeter: A Highly Efficient and Convenient Solution for Fluid Measurement

Category: Industry News

Published time: 2025-07-19

Summary:

In scenarios where large-diameter flow monitoring is required or where production shutdowns are impractical for renovation projects, Zhongce Sensing Insertion Electromagnetic Flowmeter With its unique installation method and reliable measurement performance, it has become a practical choice for numerous industrial users. Cleverly balancing ease of installation with measurement accuracy, it serves as an invaluable assistant for fluid process monitoring and management.

Core Advantages and Application Scenarios

Easy to install, cost-effective: No need to cut or shut down the pipeline—installation can be done directly through openings in the pipe, significantly reducing installation difficulty, time, and costs, especially suitable for Large-diameter pipelines ranging from DN80 to DN3000 Renovation or new construction projects.

Easy maintenance: The sensor can be hot-swapped, making daily inspections, cleaning, or replacements easy and reducing maintenance downtime.

Reliable and Durable: Adopt IP68 Protection Rating Designed to withstand industrial environments such as humidity and dust. The design features no moving parts, reducing wear-and-tear risks and ensuring long-term, stable operation.

Wide range of applicable media: Based on the principle of electromagnetic induction (Faraday's law), Suitable for measuring liquids with conductivity (typically requiring a conductivity ≥5 μS/cm). Such as water, sewage, acid-alkali solutions, slurry, pulp, and more. Commonly found in municipal water supply and drainage, wastewater treatment, industrial production processes (e.g., chemical, metallurgical, food & beverage), irrigation measurement, and other fields.

Technical Features and Measurement Performance

Stable measurement: Provides stable and repeatable flow data output, meeting the basic needs for process monitoring and cost accounting.

Wide range ratio: It features a wide flow measurement range, making it suitable for operating conditions with significant variations in flow velocity.

High-precision optional: Under ideal conditions such as meeting the straight pipe section requirements and ensuring full-pipe flow, Achieves measurement accuracy of ±0.5% to ±1.0%. (The specific accuracy level must be determined based on the model selection.)

Signal output is diverse: Typically equipped with 4-20mA analog signals, pulse outputs, and an RS485 communication interface (supporting protocols such as Modbus), making it easy to integrate with PLC, DCS, or host computer systems.

Low-power design: Suitable for battery-powered or power-constrained field applications.

Brief Overview of How It Works

The core sensors of the insertion-type electromagnetic flowmeter (including the measuring electrodes and excitation coil) are inserted directly into the fluid flowing inside the pipe. The excitation coil generates a working magnetic field, and as conductive liquid flows through it, an induced electromotive force is generated according to Faraday's law of electromagnetic induction—this force is proportional to the flow velocity. The measuring electrodes detect this electromotive force, which is then processed by a converter to produce a flow signal.

Selection and Installation Guidelines

Pipeline conditions: Confirm the pipe material, inner diameter, lining condition, and medium characteristics (temperature, pressure, electrical conductivity, corrosivity).

Installation location: Select the pipe section with stable full-tube flow, Ensure the sensor insertion depth meets the requirements. (Usually located at the pipe axis or at a specific depth), meeting the requirements for straight pipe sections of 10D upstream and 5D downstream (where D represents the pipe inner diameter).

Professional Construction: Drilling holes, welding the base (if applicable), and inserting the sensor must be performed by qualified personnel to ensure a reliable seal.

Zhongce Sensing: A Trusted Partner for Industrial Measurement

Zhongce Sensing is dedicated to providing stable and reliable industrial measurement instruments. Its insertion-type electromagnetic flowmeters are rigorously designed and manufactured in strict adherence to relevant industry standards. With proper selection and standardized installation, they can deliver exceptional performance to users. Efficient, economical, and reliable Large-diameter flow measurement solution.

Common application industries:

Municipal water network monitoring; wastewater treatment plants (influent/outflow, sludge); irrigation water measurement for agricultural use; liquid transfer in chemical processes; cooling water systems in the metallurgical industry; food and beverage production; and applications in the energy sector, such as water circulation in power plants.

Summary:

The Zhongce Sensing insertion-type electromagnetic flowmeter is an exceptionally cost-effective and practical flow measurement tool for specific application scenarios—particularly in large-diameter pipelines and retrofit projects. Its core value lies in Significantly reduces installation difficulty and costs, while delivering reliable measurement data. For users seeking efficient installation, convenient maintenance, and reliable operation, it is a solution worth considering. When making your selection, be sure to align it with the specific operating conditions and adhere to proper selection and installation guidelines, ensuring optimal performance.

Keywords: Zhongce Sensing Insertion Electromagnetic Flowmeter: A Highly Efficient and Convenient Solution for Fluid Measurement

Related information

Company News

-

Factors to consider when purchasing an intelligent electromagnetic flowmeter

Release time:2025-01-03

-

What type of flow meter is best for measuring flow rate in the petroleum industry?

Release time:2025-05-08

-

Factors to consider when purchasing a smart electromagnetic flow meter

Release time:2025-04-08

-

What type of flow meter is best suited for measuring flow rate in the petroleum industry?

Release time:2025-04-08

-

The explosion-proof performance of various instruments is extremely important in the chemical production process!

Release time:2025-04-08

Industry News

-

Precise Measurement, Smart Choice: A Comprehensive Analysis of Zhongce Sensing's Pipeline-Type Intelligent Electromagnetic Flowmeter

Release time:2025-09-23

-

Zhongce Sensing Filling Electromagnetic Flowmeter: The Core Tool for Precise Measurement

Release time:2025-09-20

-

Analysis and Application Practices of Insertion Electromagnetic Flowmeters

Release time:2025-09-17

-

Technical Analysis of Slurry-Type Electromagnetic Flowmeters

Release time:2025-09-17

-

Precision measurement, replacing imports: Newly launched filling electromagnetic flowmeters empower the beverage and pharmaceutical industries.

Release time:2025-09-12

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: Parameter, Installation, and Selection Guide

Release time:2025-08-05

-

Zhongce Sensing Electromagnetic Water Meter: The Pioneer of Precise Measurement in the Era of Smart Water Management

Release time:2025-08-05

-

Zhongce Sensing Pipeline Electromagnetic Flowmeter: Precise Measurement, the Reliable Choice for Fluid Flow Applications

Release time:2025-07-29

-

Micro and Miniature Electromagnetic Flow Meters: Small Size, Big Impact—Precision Measurement Empowers High-Precision Industries

Release time:2025-07-24

-

Zhongce Sensing's Miniature Electromagnetic Flowmeter: A Highly Efficient and Precise Choice for Measuring Small Flows

Release time:2025-07-19

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: A Highly Efficient and Convenient Solution for Fluid Measurement

Release time:2025-07-19

-

Henan Zhongce Sensor Electromagnetic Water Meter | IP68 Waterproof + Wireless Remote Transmission—Your First Choice for Smart Water Management and Precise Measurement

Release time:2025-07-16

-

Henan Zhongce Sensor Pipeline Electromagnetic Flowmeter: The Industrial Choice for High-Precision Fluid Measurement

Release time:2025-07-16

-

Micro and Miniature Electromagnetic Flow Meters: The Ideal Tool for Precisely Measuring Tiny Flow Rates

Release time:2025-07-14

-

What are the maintenance methods for electromagnetic flow meters?

Release time:2025-05-08

-

Difference between electromagnetic water meters and electromagnetic flow meters

Release time:2025-05-08

-

Advantages of electromagnetic flow meters

Release time:2025-05-08

-

Internal structure of a magnetic flow meter

Release time:2025-05-08

-

Electromagnetic flow meter principle

Release time:2025-05-08

-

Troubleshooting common malfunctions of electromagnetic flow meters

Release time:2025-05-08