Zhongce Sensing Filling Electromagnetic Flowmeter: The Core Tool for Precise Measurement

Category: Industry News

Published time: 2025-09-20

Summary: This article delves into the critical role and technical advantages of Zhongce Sensing's filling electromagnetic flowmeters in the liquid packaging industry. First, it explains how these meters operate based on Faraday's law of electromagnetic induction, enabling non-contact, high-precision measurements. The article then highlights their core benefits in filling applications: exceptional accuracy (±0.2%–0.5%), a design free of obstructive components that ensures hygiene and minimizes pressure loss, rapid response capabilities tailored for high-speed filling lines, and corrosion-resistant materials compatible with a wide range of media—including water, beverages, pharmaceuticals, and more. Additionally, the article introduces their advanced intelligent features, such as remote monitoring, self-diagnosis, and data logging functions, as well as their compliance with stringent hygiene standards specific to the food and pharmaceutical industries (e.g., 3A and EHEDG). Finally, it underscores the significant value these flowmeters bring to enhancing filling efficiency, safeguarding product quality, and reducing operational losses.

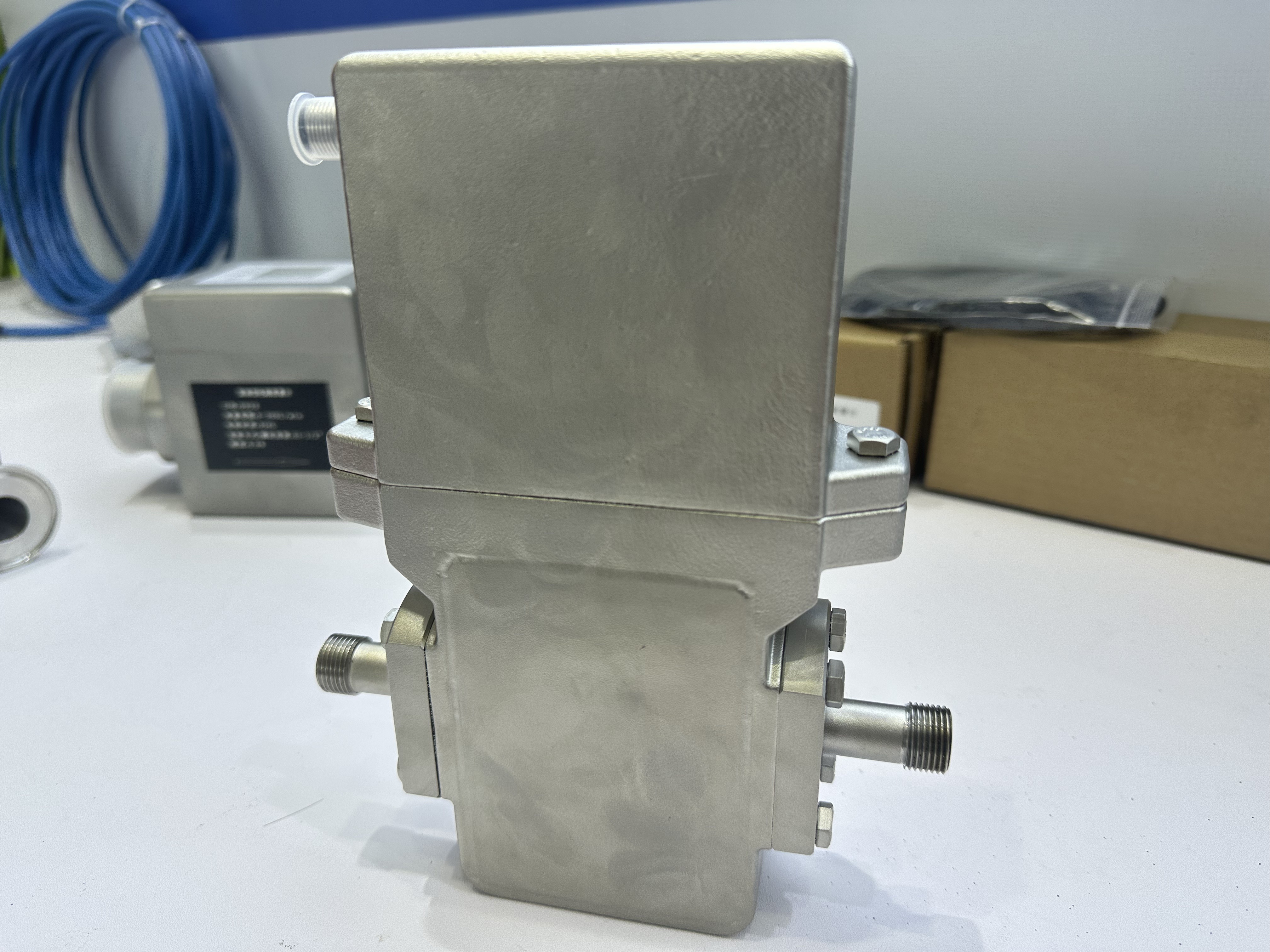

In modern liquid filling production lines—such as those for beverages, dairy products, seasonings, pharmaceuticals, and daily chemical products—accurate, reliable, and efficient flow measurement is a core component that ensures product quality, controls costs, and boosts efficiency. Zhongce Sensing's filling electromagnetic flowmeters, with their unique technical principles and tailored design, have become a highly favored key piece of equipment in this field.

I. Core Working Principle: Faraday's Law of Electromagnetic Induction

The working principle of the electromagnetic flowmeter is based on Faraday's law of electromagnetic induction in physics: When a conductive liquid flows through a measuring tube equipped with a magnetic field, an induced electromotive force (voltage) proportional to the flow velocity (i.e., volumetric flow rate) is generated. The Zhongce sensing filling electromagnetic flowmeter achieves this process through the following key components:

- Measurement tube: Typically made from non-magnetic, corrosion-resistant materials (such as stainless steel, PTFE, or PFA-lined tubing), these ensure smooth fluid flow while maintaining undisturbed magnetic fields. The inner walls are perfectly smooth and free of any flow-obstructing components, making them especially suitable for filling applications with stringent hygiene requirements.

- Excitation coil: A stable, uniform magnetic field is generated outside the measuring tube (with DC, low-frequency rectangular wave, or dual-frequency excitation technology being the mainstream approaches, effectively mitigating the effects of fluid noise and polarization voltage).

- Electrode: A pair or multiple pairs of electrodes in contact with the fluid (made of materials such as 316L stainless steel, Hastelloy, platinum-iridium alloy, tungsten carbide, etc.), used to detect the induced electromotive force (E) generated when the fluid cuts through magnetic field lines.

- Converter (Transmitter): Core processing unit. It receives electrode signals, performs amplification, filtering, and computational processing, converting the weak induced electromotive force (E) into standardized flow signals (such as 4-20mA, pulse, HART, Modbus, Profibus, etc.), and displays both instantaneous and cumulative flow rates. Modern converters are equipped with powerful intelligent features.

Its basic formula is: Q = (π * D * E) / (4 * B * k) , where Q is the volumetric flow rate, D is the inner diameter of the measuring tube, E is the induced electromotive force, B is the magnetic flux density, and k is the instrument constant. The core advantage lies in the fact that the measurement process is independent of the fluid's pressure, temperature, density, or viscosity (within a certain range)—it depends solely on flow velocity and magnetic field strength, thereby ensuring high accuracy and stability in measurements.

II. Outstanding Advantages in Filling Applications

The Zhongce Sensing filling electromagnetic flowmeter has been specially optimized for the unique requirements of the filling process, showcasing significant advantages:

- 1. High precision and high repeatability:

- Precision levels typically range from ±0.2% R to ±0.5% R (of rate), and can even be higher.

- Extremely high repeatability (typically better than ±0.1%) is crucial for ensuring consistent filling volumes across every bottle, barrel, or bag—directly impacting product quality compliance and cost control by minimizing overfilling losses.

- 2. No flow-obstructing components, low pressure loss:

- The measuring tube contains no moving or fixed components that obstruct the fluid flow; the flow cross-section is identical to that of the pipe.

- Pressure loss is minimal, equivalent only to the pressure drop across a straight pipe segment of the same length, resulting in significant energy savings—making it particularly well-suited for low-viscosity liquids and applications where maintaining low system pressure is critical.

- 3. Excellent Hygiene Performance:

- The smooth inner wall of the measuring tube (Ra ≤ 0.4 μm or lower) prevents residue buildup and facilitates easy online CIP/SIP cleaning.

- The electrodes and lining materials strictly comply with hygiene standards applicable to the food and pharmaceutical industries (such as 3-A Sanitary Standards, EHEDG, and FDA CFR 21).

- Sterile and hygienic clamp connections (e.g., compliant with DIN/SMS/IDF/RJT/ASME BPE standards) are available, ensuring zero dead legs and meeting GMP requirements.

- 4. Rapid Response and Wide Measurement Range:

- Response time is extremely short (on the millisecond level), enabling precise capture of flow rate changes at the exact moment the filling valve opens or closes, thus achieving accurate quantitative filling control—whether through batch control or flow-rate regulation.

- With a wide measurement range (typically up to 20:1 or higher), a single instrument can easily handle filling requirements across various flow rate ranges, offering exceptional flexibility.

- 5. Extensive media adaptability:

- Suitable for all liquids with a conductivity greater than approximately 5 μS/cm (such as water, juice, milk, alcoholic beverages, soy sauce, vinegar, medicinal solutions, cosmetic lotions, and more).

- Corrosion-resistant linings (PTFE, PFA, F46, rubber) and electrode materials are available, capable of handling harsh media such as strong acids, strong bases, and solvents.

- It also demonstrates good adaptability to slurries containing solid particles or fibers (note the flow rate and the wear resistance of the lining/electrodes).

- 6. Intelligent and Easy to Integrate:

- The advanced converter features:

- Self-diagnosis function: Real-time monitoring of electrode status, liner integrity, excitation systems, and more—enabling early warnings of potential failures.

- Air traffic control inspection: Prevent dry-running metering without liquid.

- Multi-parameter output: Instantaneous flow, cumulative flow, flow velocity, percentage, and more.

- Data recording: Storing historical data facilitates tracing and analysis.

- Multiple communication interfaces: Easily integrate with PLC, DCS, SCADA systems, or host computers to enable remote monitoring, parameter setting, and automated control of the filling process.

- Batch Control Function: Built-in batch controller allows direct drive of the filling valve, enabling high-precision, quantitative filling.

- The advanced converter features:

- 7. Relatively simple installation and maintenance:

- The requirements for the straight pipe section are relatively low (typically 5D upstream and 3D downstream, where D represents the pipe diameter).

- No mechanically worn components, requiring minimal maintenance and offering a long service life. The primary maintenance tasks involve regular inspection and cleaning of the electrodes (some models feature an automatic electrode-cleaning function).

III. Selection and Application Considerations

To fully leverage the advantages of Zhongce Sensing's filling electromagnetic flowmeters, selection and application should consider:

- Media characteristics: Electrical conductivity (must meet standards), corrosivity, temperature, pressure, presence of particles/bubbles, and hygiene level requirements.

- Pipeline parameters: Pipe diameter (DN), flow range (minimum/normal/maximum flow), and installation direction (avoid air bubbles accumulating around the electrodes; when installing horizontally, the electrodes should not be positioned directly above each other).

- Lining and electrode materials: Select based on the corrosivity of the medium, temperature, abrasiveness, and hygiene requirements.

- Excitation method: Choose based on precision and anti-interference requirements (e.g., dual-frequency excitation offers strong anti-interference capability, even against issues like slurry noise and bubbles).

- Protection Level: On-site environment (IP65/IP67/IP68).

- Certification requirements: Clearly determine whether explosion-proof certification (such as ATEX, IECEx) or hygiene certifications (like 3A, EHEDG) are required.

- Grounding: Good grounding is key to ensuring measurement stability and immunity to interference, especially for separated-type sensors. Installation must be carried out strictly according to the instructions provided.

- Avoid strong electromagnetic interference sources: Stay away from large motors, frequency converters, and similar equipment.

Conclusion:

The Zhongce Sensing Filling Electromagnetic Flowmeter, with its non-contact measurement principle based on electromagnetic induction, combined with high precision, zero pressure loss, hygienic design, rapid response, and intelligent features optimized specifically for filling processes, has become the core equipment enabling precise measurement, efficient control, quality assurance, and cost optimization in modern liquid filling production lines. Its reliability and ease of use have made it widely adopted across numerous industries, including food & beverage, pharmaceuticals, and daily chemicals. Proper selection, installation, and maintenance can maximize its performance, ensuring both operational efficiency and product quality for your business.

Keywords: Zhongce Sensing Filling Electromagnetic Flowmeter: The Core Tool for Precise Measurement

Related information

Company News

-

Factors to consider when purchasing an intelligent electromagnetic flowmeter

Release time:2025-01-03

-

What type of flow meter is best for measuring flow rate in the petroleum industry?

Release time:2025-05-08

-

Factors to consider when purchasing a smart electromagnetic flow meter

Release time:2025-04-08

-

What type of flow meter is best suited for measuring flow rate in the petroleum industry?

Release time:2025-04-08

-

The explosion-proof performance of various instruments is extremely important in the chemical production process!

Release time:2025-04-08

Industry News

-

Precise Measurement, Smart Choice: A Comprehensive Analysis of Zhongce Sensing's Pipeline-Type Intelligent Electromagnetic Flowmeter

Release time:2025-09-23

-

Zhongce Sensing Filling Electromagnetic Flowmeter: The Core Tool for Precise Measurement

Release time:2025-09-20

-

Analysis and Application Practices of Insertion Electromagnetic Flowmeters

Release time:2025-09-17

-

Technical Analysis of Slurry-Type Electromagnetic Flowmeters

Release time:2025-09-17

-

Precision measurement, replacing imports: Newly launched filling electromagnetic flowmeters empower the beverage and pharmaceutical industries.

Release time:2025-09-12

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: Parameter, Installation, and Selection Guide

Release time:2025-08-05

-

Zhongce Sensing Electromagnetic Water Meter: The Pioneer of Precise Measurement in the Era of Smart Water Management

Release time:2025-08-05

-

Zhongce Sensing Pipeline Electromagnetic Flowmeter: Precise Measurement, the Reliable Choice for Fluid Flow Applications

Release time:2025-07-29

-

Micro and Miniature Electromagnetic Flow Meters: Small Size, Big Impact—Precision Measurement Empowers High-Precision Industries

Release time:2025-07-24

-

Zhongce Sensing's Miniature Electromagnetic Flowmeter: A Highly Efficient and Precise Choice for Measuring Small Flows

Release time:2025-07-19

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: A Highly Efficient and Convenient Solution for Fluid Measurement

Release time:2025-07-19

-

Henan Zhongce Sensor Electromagnetic Water Meter | IP68 Waterproof + Wireless Remote Transmission—Your First Choice for Smart Water Management and Precise Measurement

Release time:2025-07-16

-

Henan Zhongce Sensor Pipeline Electromagnetic Flowmeter: The Industrial Choice for High-Precision Fluid Measurement

Release time:2025-07-16

-

Micro and Miniature Electromagnetic Flow Meters: The Ideal Tool for Precisely Measuring Tiny Flow Rates

Release time:2025-07-14

-

What are the maintenance methods for electromagnetic flow meters?

Release time:2025-05-08

-

Difference between electromagnetic water meters and electromagnetic flow meters

Release time:2025-05-08

-

Advantages of electromagnetic flow meters

Release time:2025-05-08

-

Internal structure of a magnetic flow meter

Release time:2025-05-08

-

Electromagnetic flow meter principle

Release time:2025-05-08

-

Troubleshooting common malfunctions of electromagnetic flow meters

Release time:2025-05-08