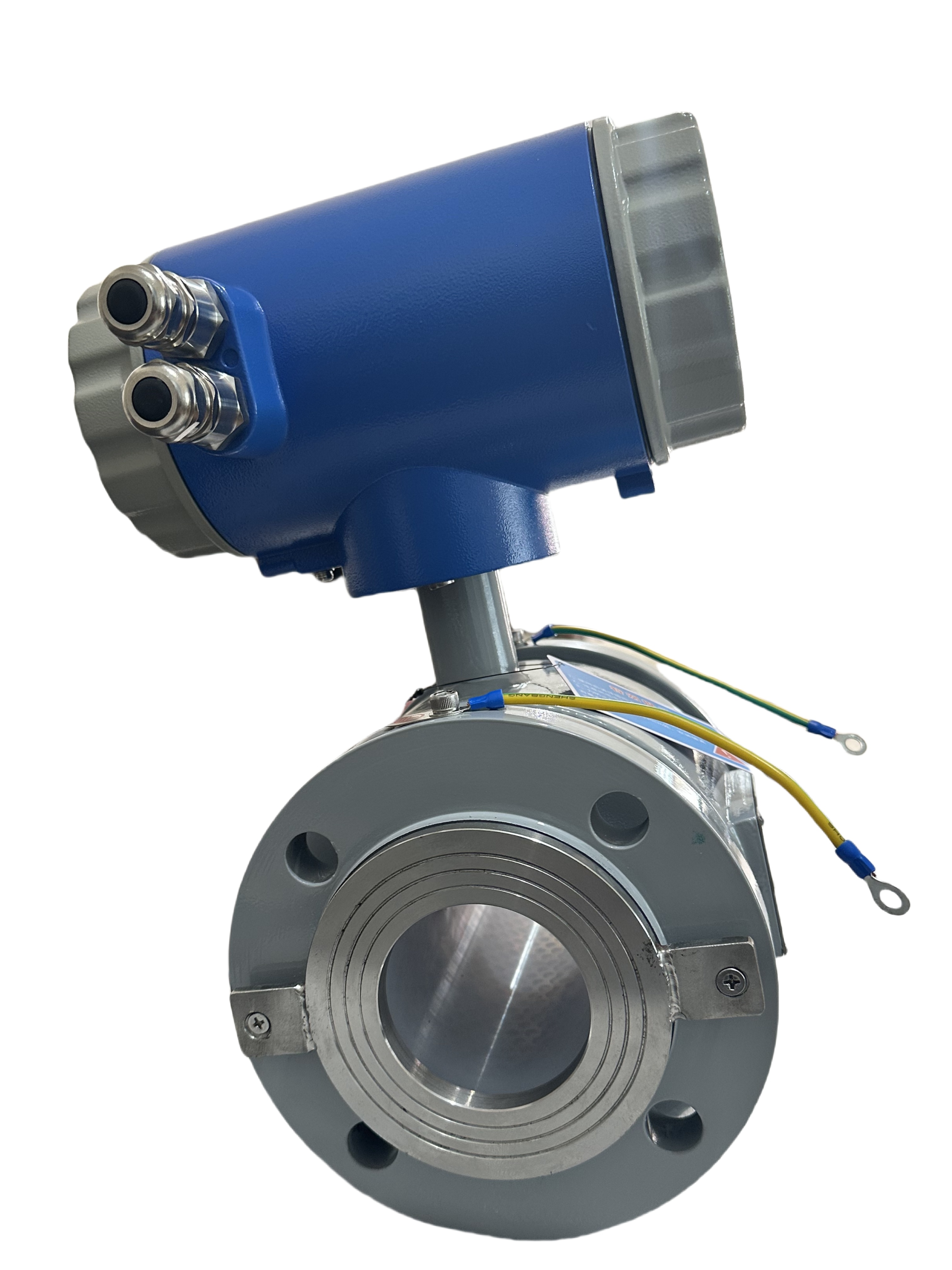

Technical Analysis of Slurry-Type Electromagnetic Flowmeters

Category: Industry News

Published time: 2025-09-17

Summary: The slurry-type electromagnetic flowmeter is a device specifically designed to measure the flow rate of conductive slurries, operating on the principle of electromagnetic induction. It is well-suited for media containing solid particles, such as mud and mineral slurries, and is widely used in industries including chemical processing, mining, and water treatment. This article introduces its working principle, key features, application scenarios, advantages and disadvantages, as well as essential maintenance tips, emphasizing its critical role in industrial automation.

The slurry-type electromagnetic flowmeter is a specialized type of electromagnetic flowmeter designed specifically for measuring conductive slurries—such as mud, mineral slurries, or suspended solids in wastewater. It plays a critical role in industrial process control, ensuring accurate and reliable flow measurements.

How it works

The liquid-type electromagnetic flowmeter is based on Faraday's law of electromagnetic induction: When a conductive fluid passes through an applied magnetic field, an induced voltage proportional to the flow velocity is generated within the fluid. The specific process involves:

- Magnetic field generation : A stable magnetic field is generated within the measuring tube via the coil.

- Voltage Detection : Charged particles in the fluid cut through magnetic field lines, generating a tiny voltage signal at the electrodes.

- Signal Processing :The converter amplifies the voltage signal and calculates it into a flow value, typically expressed in cubic meters per hour or gallons per minute.

This principle makes it suitable only for conductive liquids (typically requiring a conductivity greater than 5 μS/cm), but with optimized design, it can effectively handle slurries with high solid content.

Core Features

The design of the slurry-type electromagnetic flowmeter addresses the challenges posed by slurry media:

- Wear-resistant lining : Utilizing rubber, polyurethane, or ceramic materials as pipe linings to resist erosion and corrosion caused by solid particles.

- Anti-clogging electrode Electrodes are typically designed as either scraper-style or detachable, making it easy to clean off deposits and prevent measurement errors.

- No moving parts Compared to mechanical flow meters, it features no impeller or rotor, reducing wear and lowering maintenance requirements.

- Wide measurement range : Supports both high- and low-flow measurements, with a range ratio of up to 10:1 or higher, making it suitable for applications with significant flow fluctuations.

Application scenarios

This flow meter is widely used across multiple industries:

- Mining : Used for monitoring slurry flow in the mineral processing circuit, ensuring efficient separation and resource recovery.

- Chemical engineering : Measures corrosive slurries (such as acid-alkali mixtures), enabling precise control of reaction vessels.

- Water Treatment : Monitoring sludge flow at the wastewater treatment plant to optimize the sedimentation and dewatering processes.

- Food Industry : Handling pulp- or particle-containing fluids, such as juice or sauce production, in compliance with hygiene standards.

Real-world example: At a mineral processing plant, slurry-type electromagnetic flowmeters can reduce downtime caused by solid buildup, boosting production efficiency by more than 20%.

Advantages and Disadvantages

Advantages :

- High precision : Measurement errors typically remain below ±0.5%, making it suitable for stringent quality control.

- Corrosion resistance : The lining and electrode materials (such as Hastelloy) are resistant to chemical corrosion.

- Low maintenance : No mechanical components, with a lifespan of over 10 years, reducing operational costs.

- Environmentally friendly : No pressure loss, energy-efficient, and reduces the risk of leakage.

Disadvantages :

- Electrical conductivity requirements : Non-conductive liquids (such as oils) cannot be measured directly and require additional pre-processing.

- Installation Restrictions : Installation must be done with the pipe fully filled to prevent bubble interference, and the pipeline must be grounded to ensure signal stability.

- Higher costs : The initial investment is higher than that of a turbine flowmeter, but the long-term returns are significant.

Installation and Maintenance Essentials

Correct installation is key to ensuring performance:

- Installation Location : Choose straight pipe sections (5 times the pipe diameter upstream, 2 times downstream) to avoid disturbances caused by elbows and valves.

- Grounding Requirements : Must be reliably grounded to prevent electromagnetic interference from causing signal drift.

- Maintenance Practices :

- Clean the electrodes regularly (every 3–6 months) using a soft brush or high-pressure water rinsing.

- Inspect the liner for wear and replace it promptly to prevent leaks.

- Calibrate the converter annually to ensure accurate readings.

Future Trends

With the development of Industry 4.0, slurry-type electromagnetic flowmeters are evolving toward intelligentization:

- Integrated Internet of Things : By transmitting data to the cloud platform in real time via sensors, predictive maintenance is achieved.

- Materials Innovation : Developing nano-coating linings to enhance wear resistance and extend service life.

- Green Application Expanding into the renewable energy sector (such as biomass slurry treatment) to support sustainable development.

In summary, the slurry-type electromagnetic flowmeter has become a core tool for industrial flow measurement thanks to its reliability and versatility. With proper selection and maintenance, it can significantly enhance process efficiency and safety.

Keywords: Technical Analysis of Slurry-Type Electromagnetic Flowmeters

Related information

Company News

-

Factors to consider when purchasing an intelligent electromagnetic flowmeter

Release time:2025-01-03

-

What type of flow meter is best for measuring flow rate in the petroleum industry?

Release time:2025-05-08

-

Factors to consider when purchasing a smart electromagnetic flow meter

Release time:2025-04-08

-

What type of flow meter is best suited for measuring flow rate in the petroleum industry?

Release time:2025-04-08

-

The explosion-proof performance of various instruments is extremely important in the chemical production process!

Release time:2025-04-08

Industry News

-

Precise Measurement, Smart Choice: A Comprehensive Analysis of Zhongce Sensing's Pipeline-Type Intelligent Electromagnetic Flowmeter

Release time:2025-09-23

-

Zhongce Sensing Filling Electromagnetic Flowmeter: The Core Tool for Precise Measurement

Release time:2025-09-20

-

Analysis and Application Practices of Insertion Electromagnetic Flowmeters

Release time:2025-09-17

-

Technical Analysis of Slurry-Type Electromagnetic Flowmeters

Release time:2025-09-17

-

Precision measurement, replacing imports: Newly launched filling electromagnetic flowmeters empower the beverage and pharmaceutical industries.

Release time:2025-09-12

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: Parameter, Installation, and Selection Guide

Release time:2025-08-05

-

Zhongce Sensing Electromagnetic Water Meter: The Pioneer of Precise Measurement in the Era of Smart Water Management

Release time:2025-08-05

-

Zhongce Sensing Pipeline Electromagnetic Flowmeter: Precise Measurement, the Reliable Choice for Fluid Flow Applications

Release time:2025-07-29

-

Micro and Miniature Electromagnetic Flow Meters: Small Size, Big Impact—Precision Measurement Empowers High-Precision Industries

Release time:2025-07-24

-

Zhongce Sensing's Miniature Electromagnetic Flowmeter: A Highly Efficient and Precise Choice for Measuring Small Flows

Release time:2025-07-19

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: A Highly Efficient and Convenient Solution for Fluid Measurement

Release time:2025-07-19

-

Henan Zhongce Sensor Electromagnetic Water Meter | IP68 Waterproof + Wireless Remote Transmission—Your First Choice for Smart Water Management and Precise Measurement

Release time:2025-07-16

-

Henan Zhongce Sensor Pipeline Electromagnetic Flowmeter: The Industrial Choice for High-Precision Fluid Measurement

Release time:2025-07-16

-

Micro and Miniature Electromagnetic Flow Meters: The Ideal Tool for Precisely Measuring Tiny Flow Rates

Release time:2025-07-14

-

What are the maintenance methods for electromagnetic flow meters?

Release time:2025-05-08

-

Difference between electromagnetic water meters and electromagnetic flow meters

Release time:2025-05-08

-

Advantages of electromagnetic flow meters

Release time:2025-05-08

-

Internal structure of a magnetic flow meter

Release time:2025-05-08

-

Electromagnetic flow meter principle

Release time:2025-05-08

-

Troubleshooting common malfunctions of electromagnetic flow meters

Release time:2025-05-08