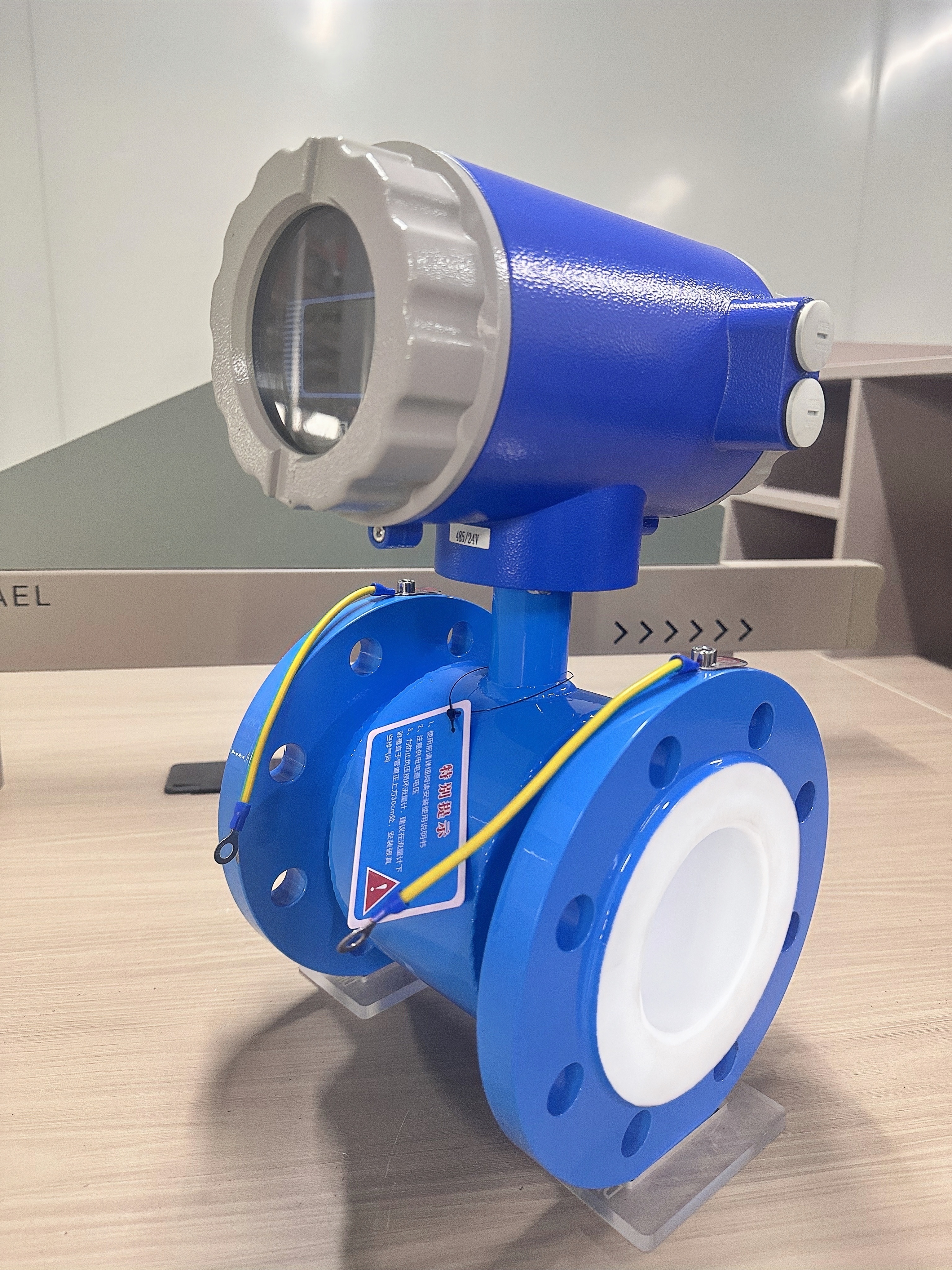

Zhongce Sensing Pipeline Electromagnetic Flowmeter: Precise Measurement, the Reliable Choice for Fluid Flow Applications

Category: Industry News

Published time: 2025-07-29

Summary:

In numerous fields such as industrial production, municipal water management, environmental monitoring, and the food and pharmaceutical industries, precise, stable, and reliable measurement of fluid flow within pipelines—especially conductive liquids—is crucial. Whether it’s for process control, energy management, trade settlement, or environmental regulation, the accuracy of flow data directly impacts efficiency, costs, and compliance. Among the many flow measurement technologies available, Electromagnetic Flowmeter With its unique advantages, it has become one of the preferred solutions for measuring conductive liquid flow. As a leading domestic brand in flow instrumentation, Zhongce Sensing With its deep-rooted technological expertise and rigorous quality control, its Pipeline Electromagnetic Flowmeter It has earned widespread recognition in the market. This article will delve into the working principle, key advantages, typical application scenarios, and crucial selection criteria of Zhongce Sensing's pipeline-type electromagnetic flowmeters, helping you find a reliable solution for fluid measurement.

I. Principle Unveiled: Industrial Applications of Faraday's Law

The core working principle of Zhongce Sensing's pipeline-type electromagnetic flowmeter is based on Faraday's Law of Electromagnetic Induction Its structure is primarily composed of the following parts:

Measurement tube: It is typically made from non-magnetic materials (such as stainless steel) and lined with insulating materials (like PTFE, rubber, polyurethane, etc.), ensuring that the fluid remains electrically isolated from the measuring electrodes.

Excitation coil: Installed on the outer side of the measuring tube and supplied with a stable excitation current, it generates a uniform magnetic field within the measuring tube that is perpendicular to the direction of fluid flow.

Measurement electrode: A pair or multiple pairs of electrodes are precisely installed on the inner wall of the measuring tube, making direct contact with the fluid to detect the induced electromotive force.

Work process:

When a conductive liquid flows through a magnetic field region, it is equivalent to a conductor moving across magnetic field lines. According to Faraday's law, this induces an electromotive force (EMF) within the liquid. The magnitude of this EMF is directly proportional to the average flow velocity of the fluid—specifically, its volumetric flow rate—and its direction is perpendicular to both the magnetic field and the direction of fluid flow. Measurement electrodes detect this weak EMF signal, which is then amplified, filtered, processed mathematically, and digitized by a converter (transmitter). The result is a precise measurement of the volumetric flow rate.

Key points:

Only applicable to Electrical conductivity ≥ 5 μS/cm Liquids (such as water, acids, bases, salt solutions, mud, pulp, and more).

Measurement results Unaffected by changes in fluid density, viscosity, temperature, or pressure (within a certain range). 。

No moving parts, no pressure loss , which has minimal impact on the fluid flow state.

II. Core Advantages of Zhongce Sensing Pipeline Electromagnetic Flowmeters

Zhongce Sensing's products inherit the widespread advantages of electromagnetic flowmeters while, through meticulous design and manufacturing, highlighting their own competitive edge:

High Precision and Stability:

By employing advanced excitation technology and signal processing algorithms, it effectively suppresses power frequency interference and fluid noise.

Carefully designed flow channel structures and electrode configurations ensure uniform flow velocity distribution and excellent measurement linearity.

It features low long-term drift, excellent repeatability, and meets the requirements for trade settlement and high-precision process control.

Wide applicability and compatibility:

Multiple lining material options: Such as PTFE (highly corrosive, high-temperature), F46, rubber (wear-resistant, mildly corrosive), polyurethane (highly wear-resistant), and more—catering to diverse operating conditions including strong acids, strong bases, abrasive slurries, and sanitary-grade media.

Multiple electrode material options: Such materials as 316L stainless steel, Hastelloy C alloy, titanium, tantalum, and platinum-iridium alloy meet the requirements for various corrosive media.

Wide caliber range: We offer a wide range of specifications, from DN10 to DN3000 and even larger, covering measurement applications from tiny flow rates to those in large-diameter pipes.

Multiple outputs and communications: Standard features include 4-20mA analog output, pulse/frequency output, and support for fieldbus protocols such as HART, MODBUS, Profibus DP, and FF, making it easy to integrate into DCS/PLC systems.

Robust and reliable, with easy maintenance:

The measurement tube features a robust structure and typically achieves protection ratings of up to IP65/IP67/IP68 (in either split or integrated designs), making it suitable for harsh industrial environments.

Flow-through design without obstructions: Nearly zero pressure loss, energy-efficient and resistant to clogging—perfectly suited for fluids containing solid particles or fibers, such as mineral slurries, wastewater, and pulp.

No mechanical moving parts, minimal wear, low failure rate, and extended service life.

Some models are supported. Air Traffic Control Inspection And Electrode self-cleaning/self-diagnosis Function, reducing maintenance workload.

Intelligence and Convenience:

The smart converter features a large-screen LCD display that intuitively shows real-time flow rate, cumulative flow, flow velocity, percentage readings, alarm status, and more.

Parameter settings are convenient, supporting key operations or configuration via handheld terminals/communication.

Equipped with functions such as data logging and self-diagnostic fault detection, it facilitates operation and maintenance management.

Compliance with Standards and Certifications:

Product design and manufacturing comply with relevant national standards (GB/T) and international standards (such as IEC).

By obtaining certifications such as the ISO9001 quality management system, we ensure the consistency and reliability of our products.

3. Typical Application Scenarios

Zhongce Sensing's pipeline-type electromagnetic flowmeters, thanks to their advantages, are widely used in the following fields:

Water Treatment Industry: Raw water/city water inflow/outflow measurement, wastewater treatment plant influent/effluent and process control, chemical dosing measurement, and reclaimed water reuse.

Chemical Engineering and Petrochemicals: Precise measurement and control of various acid, alkali, and salt solutions, as well as additives and liquid raw materials/products.

Metallurgy and Mining: Flow measurement of mineral slurry, cooling water, circulating water, and process water.

Food and Beverage: High-hygiene fluid measurement applications such as water, fruit juices, milk, alcoholic beverages, and syrups—requiring hygienic design features like Tri-Clamp clamp connections and polished finishes.

Pharmaceutical Industry: Flow monitoring for purified water, Water for Injection (WFI), process solutions, and CIP/SIP cleaning fluids.

Energy Industry: Measurement of cooling circulating water, boiler feedwater, and supply/return water for the heating network.

Environmental Monitoring: Total pollutant emission monitoring and flow measurement integrated with the online water quality monitoring system.

Irrigation and Water Resources: Agricultural irrigation water measurement, and channel/pipeline water conveyance measurement.

IV. Guide to Key Selection Factors

To ensure that the Zhongce Sensing pipeline-type electromagnetic flowmeter delivers optimal performance in your application, you should carefully consider the following factors during selection:

Media characteristics:

Electrical conductivity: Must be ≥5 μS/cm (minimum requirement; specific models may have higher standards).

Corrosive: Determine the optimal material combination for linings and electrodes (e.g., PTFE lining + tantalum electrode for strong acids).

Temperature range: The selected lining and excitation coil must be able to withstand the medium's maximum/minimum temperature.

Pressure range: The pipeline working pressure must be within the flowmeter's rated pressure range.

Does it contain solid particles/fiber? Choose wear-resistant linings (such as polyurethane or ceramic) and maintain an appropriate flow rate (to prevent sedimentation).

Health requirements: The food and pharmaceutical industries require hygienic designs (smoothness, clamp connections, and no dead corners).

Process parameters:

Pipe diameter (DN): Determine the dimensions of the flowmeter body.

Flow range (minimum/normal/maximum): Ensuring that the common flow rate remains within approximately 30%-70% of the flow meter's range is optimal—avoiding exceeding the maximum flow limit while keeping the minimum flow above the measurable lower threshold.

Installation method and flow direction: Typically, installation requires the pipe to be fully filled, and the flow direction must align with the sensor markings. Be sure to observe the requirements for straight pipe sections (a common minimum is 5D upstream and 3D downstream, but refer to the manual for specifics).

Environmental conditions:

Ambient temperature, humidity.

Explosion-proof requirements (if installation in an explosive environment is necessary, select explosion-proof certified products).

Ingress Protection (IP) Rating.

Output and Communication Requirements:

What signal outputs are required (4-20mA, pulse)?

Is fieldbus communication required (HART, MODBUS, Profibus, etc.)

Is a split-type installation required (separating the converter from the sensor, suitable for high-temperature or hard-to-observe environments)?

Conclusion: A Trusted Partner for Fluid Measurement

Zhongce Sensing's pipeline-type electromagnetic flowmeter combines mature electromagnetic measurement principles with sophisticated manufacturing techniques, offering a highly accurate, reliable, and low-maintenance solution for measuring the flow of conductive liquids. Its wide range of applicability, flexible configuration options, and robust, durable design enable it to effortlessly handle diverse challenges—ranging from clean water to complex slurries, from tiny pipe diameters to large-scale pipelines, and from standard industrial environments to demanding operational conditions.

When selecting a flow meter, thoroughly understanding your specific application needs and referring to the selection guidelines provided in this article will help you precisely match the most suitable Zhongce Sensing product. By choosing Zhongce Sensing, you’re not only acquiring a sophisticated measurement instrument—but also partnering with a trusted, long-term collaborator in the field of fluid measurement, providing robust data support for your production process control, energy management, trade settlement, and environmental protection efforts.

Keywords: Zhongce Sensing Pipeline Electromagnetic Flowmeter: Precise Measurement, the Reliable Choice for Fluid Flow Applications

Related information

Company News

-

Factors to consider when purchasing an intelligent electromagnetic flowmeter

Release time:2025-01-03

-

What type of flow meter is best for measuring flow rate in the petroleum industry?

Release time:2025-05-08

-

Factors to consider when purchasing a smart electromagnetic flow meter

Release time:2025-04-08

-

What type of flow meter is best suited for measuring flow rate in the petroleum industry?

Release time:2025-04-08

-

The explosion-proof performance of various instruments is extremely important in the chemical production process!

Release time:2025-04-08

Industry News

-

Precise Measurement, Smart Choice: A Comprehensive Analysis of Zhongce Sensing's Pipeline-Type Intelligent Electromagnetic Flowmeter

Release time:2025-09-23

-

Zhongce Sensing Filling Electromagnetic Flowmeter: The Core Tool for Precise Measurement

Release time:2025-09-20

-

Analysis and Application Practices of Insertion Electromagnetic Flowmeters

Release time:2025-09-17

-

Technical Analysis of Slurry-Type Electromagnetic Flowmeters

Release time:2025-09-17

-

Precision measurement, replacing imports: Newly launched filling electromagnetic flowmeters empower the beverage and pharmaceutical industries.

Release time:2025-09-12

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: Parameter, Installation, and Selection Guide

Release time:2025-08-05

-

Zhongce Sensing Electromagnetic Water Meter: The Pioneer of Precise Measurement in the Era of Smart Water Management

Release time:2025-08-05

-

Zhongce Sensing Pipeline Electromagnetic Flowmeter: Precise Measurement, the Reliable Choice for Fluid Flow Applications

Release time:2025-07-29

-

Micro and Miniature Electromagnetic Flow Meters: Small Size, Big Impact—Precision Measurement Empowers High-Precision Industries

Release time:2025-07-24

-

Zhongce Sensing's Miniature Electromagnetic Flowmeter: A Highly Efficient and Precise Choice for Measuring Small Flows

Release time:2025-07-19

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: A Highly Efficient and Convenient Solution for Fluid Measurement

Release time:2025-07-19

-

Henan Zhongce Sensor Electromagnetic Water Meter | IP68 Waterproof + Wireless Remote Transmission—Your First Choice for Smart Water Management and Precise Measurement

Release time:2025-07-16

-

Henan Zhongce Sensor Pipeline Electromagnetic Flowmeter: The Industrial Choice for High-Precision Fluid Measurement

Release time:2025-07-16

-

Micro and Miniature Electromagnetic Flow Meters: The Ideal Tool for Precisely Measuring Tiny Flow Rates

Release time:2025-07-14

-

What are the maintenance methods for electromagnetic flow meters?

Release time:2025-05-08

-

Difference between electromagnetic water meters and electromagnetic flow meters

Release time:2025-05-08

-

Advantages of electromagnetic flow meters

Release time:2025-05-08

-

Internal structure of a magnetic flow meter

Release time:2025-05-08

-

Electromagnetic flow meter principle

Release time:2025-05-08

-

Troubleshooting common malfunctions of electromagnetic flow meters

Release time:2025-05-08