Micro and Miniature Electromagnetic Flow Meters: Small Size, Big Impact—Precision Measurement Empowers High-Precision Industries

Category: Industry News

Published time: 2025-07-24

Summary:

In the industrial sector, where precision control is paramount, traditional large-scale flow meters often find themselves "without a stage to shine." Whether it's navigating the intricate piping systems within medical devices, ensuring precise dosing in wastewater treatment plants, or measuring minute flow rates during small-scale bottling operations on food and beverage production lines— Ultra-small caliber, ultra-high precision, miniaturized volume Flow measurement devices have become a critical necessity. The miniature electromagnetic flowmeter was specifically developed to overcome these precise measurement challenges.

I. Industry Pain Point: The Bottleneck Challenge in Measuring Small Flow Rates

Take two typical scenarios as examples:

Medical devices (such as hemodialysis machines, automated dispensing systems): The formulation of the medication solution and the delivery of saline must be precise down to the milliliter—or even micro-liter level. The tubing is extremely thin (DN6 to DN15 is common), and the fluids may be corrosive (such as disinfectants), while the equipment itself must fit into an incredibly compact space. Traditional mechanical or ultrasonic flow meters may fall short due to their bulky size, insufficient accuracy, lack of corrosion resistance, or susceptibility to interference.

Wastewater treatment (e.g., precise dosing processes): The dosage of chemical agents such as flocculants and carbon sources directly affects both the treatment efficiency and the cost. Typically, the dosing points are located in bypass lines or small pipelines (DN15–DN50), where flow rates are minimal and may even fluctuate intermittently—especially when driven by metering pumps. Therefore, the flow meters used must be resistant to corrosive media, offer rapid response times, maintain high accuracy, and reliably capture these pulsating flow conditions.

These scenes collectively call out: A compact, high-precision, corrosion-resistant solution capable of measuring ultra-low/pulsating flow rates. 。

II. Micro and Miniature Electromagnetic Flow Meters: The Core Tool for Precise Breakthroughs

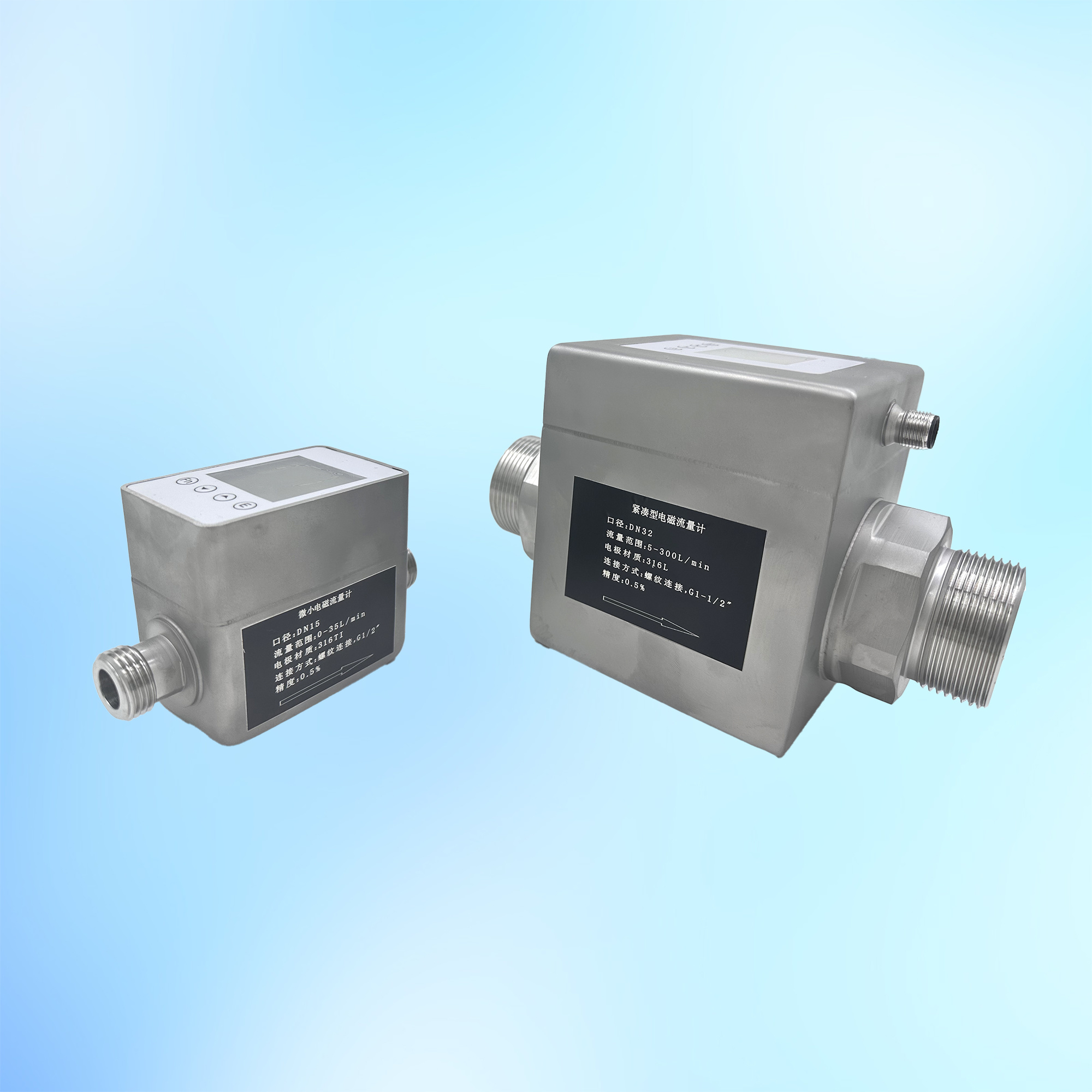

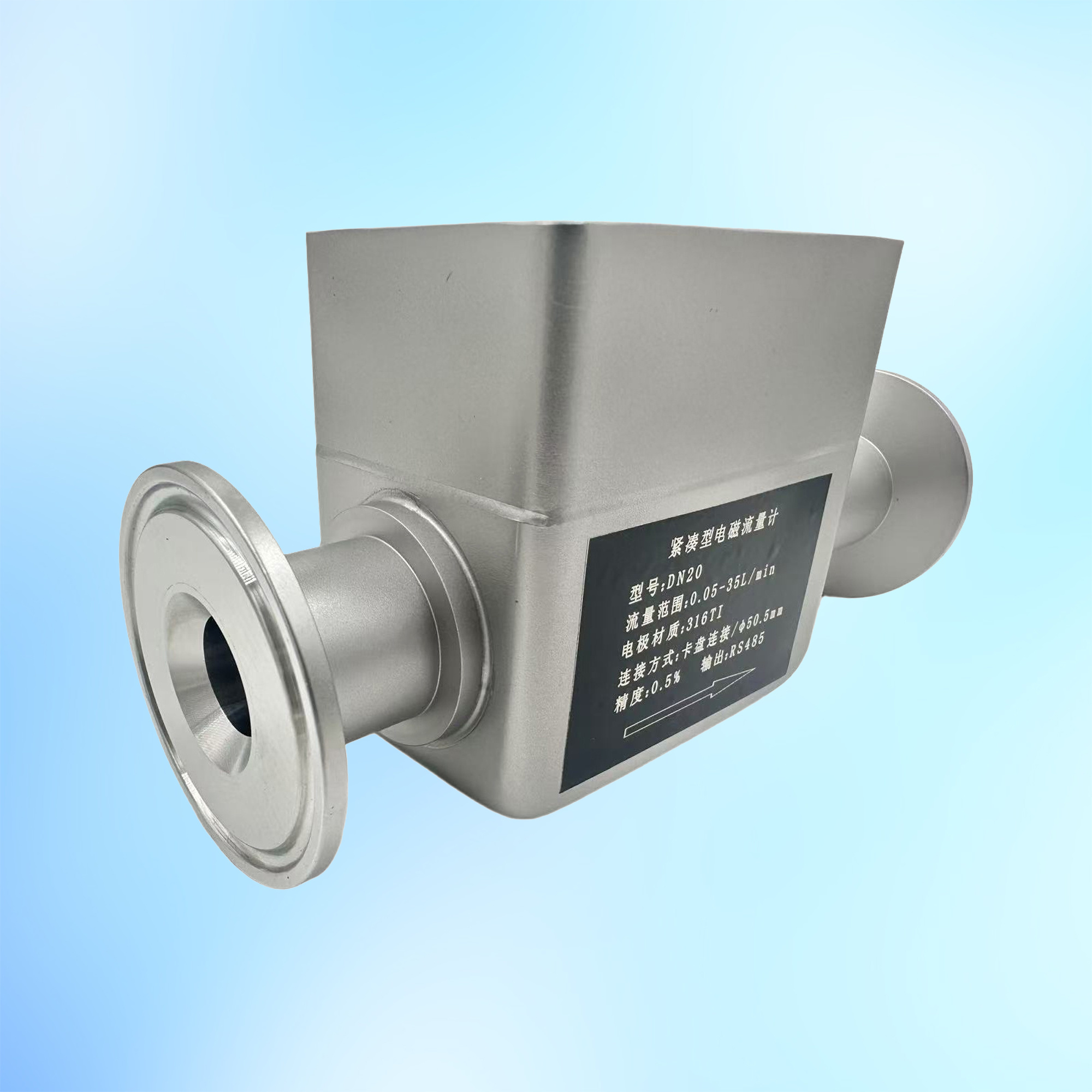

Based on the well-established principle of electromagnetic flowmeters, the miniaturized design has given rise to micro-sized electromagnetic flowmeters (such as the typical DN6-DN50 models), making them the ideal solution to address the challenges mentioned above. Their core advantages include:

Microscopic volume, seamlessly integrated: Its structure is compact (especially with its integrated design), significantly shorter than conventional flow meters, and lightweight. It can be easily integrated into the limited space inside medical devices or installed on the narrow dosing pipelines of wastewater treatment plants, causing minimal disruption to the existing system layout.

Ultra-low flow,精准捕捉: Breaking through traditional limits, the flow range can go as low as 0.05 liters per minute (DN6), offering exceptionally high resolution. Whether it's delivering tiny volumes of medication in medical applications or adding milliliter-level chemicals in wastewater treatment plants, this capability ensures precise and reliable performance. Stable and reliable Precise measurement avoids waste or suboptimal results caused by "measurement uncertainty."

Tolerant to harsh conditions, stable and reliable:

Corrosion-resistant: Measurement tubes are commonly lined with advanced engineering plastics such as PEEK, while electrodes can be selected from materials like 316Ti, Hastelloy, or titanium. These solutions effortlessly handle chemical disinfectants used in medical applications, as well as corrosive agents found in wastewater—such as sodium hypochlorite, acids, or bases. Extend service life, ensure data reliability 。

No flow-obstructing components: The electromagnetic principle features no moving parts and exhibits excellent adaptability to fluids containing tiny particles—such as trace crystals in pharmaceutical solutions or flocs formed during dosing. Not easily clogged, with extremely low maintenance requirements , particularly suitable for medical devices that require uninterrupted operation and automated dosing systems.

Pulse-resistant: Excellent dynamic response characteristics effectively handle flow pulsations generated by equipment such as metering pumps, providing Real-time, continuous instantaneous flow feedback , laying the foundation for precise control (such as PID regulation of dosing pumps).

High-precision measurement, reliable data: Accuracy can reach ±0.2% or ±0.5%, significantly higher than many other principles of small-flow meters. In demanding applications requiring precise ratios—such as dialysate preparation—or in cost-sensitive dosing scenarios, like the addition of expensive carbon sources, A tiny improvement in precision can mean significant quality assurance or cost savings. 。

Multiple interfaces and signals for flexible integration: Offering a variety of miniature connection methods such as threads, clamps, and flanges to suit different piping systems. Rich output signals available (pulse, frequency, switch output, 4-20mA, RS485 Modbus). Easily interface with PLC, DCS, SCADA systems, or internal device controllers. , enabling remote data transmission, alarming, and automatic control.

III. Deepening Expansion of Application Scenarios

Besides medical and eco-friendly water treatment, its application potential is vast:

Food and Beverage: Precise control of trace additions of spices, additives, and concentrated juices; filling and metering for small-scale canning/batch processing lines.

Fine Chemicals: Precise measurement and proportioning of corrosive chemicals and expensive raw materials on laboratory-scale or small production-line setups.

Semiconductors: Monitoring and controlling extremely low flow rates of ultrapure water and high-purity chemical solutions.

Energy: Precise water replenishment and additive dosing control for small boilers or cooling systems.

4. Key Considerations for Selection and Application

Electrical conductivity: The fluid conductivity must be ≥20 μS/cm (pure water and oils are not applicable).

Full pipe: It is essential to ensure that the measuring tube remains fully filled with fluid at all times.

Grounding: Good grounding (liquid contact) is key to both noise immunity and accuracy assurance.

Flow rate: It is recommended to use 1–4 m/s for general fluids or 1–3 m/s for fluids containing particles. Flow rates that are too low may affect accuracy, while excessively high velocities could accelerate wear. If necessary, flow rate can be adjusted using a reducer.

Installation location: Meet the requirements for straight pipe sections upstream and downstream (3D upstream, 1D downstream), with proper orientation. Vertical installation helps prevent sediment buildup.

Summary

The micro-sized electromagnetic flowmeter, thanks to its Miniaturized, high-precision, corrosion-resistant, low-maintenance Its core feature provides an outstanding solution to the challenging task of small-flow, high-precision measurement across numerous fields, including medical devices, eco-friendly water treatment, food and beverage production, and fine chemicals. Not only does it fill critical gaps in traditional measurement techniques, but it also serves as a key sensor driving the advancement of cutting-edge industries toward smarter, more efficient, and highly reliable automated control systems. In today’s pursuit of "lean manufacturing" and "precise control," this compact yet powerful flow-measurement tool is playing an indispensable and vital role.

Keywords: Micro and Miniature Electromagnetic Flow Meters: Small Size, Big Impact—Precision Measurement Empowers High-Precision Industries

Related information

Company News

-

Factors to consider when purchasing an intelligent electromagnetic flowmeter

Release time:2025-01-03

-

What type of flow meter is best for measuring flow rate in the petroleum industry?

Release time:2025-05-08

-

Factors to consider when purchasing a smart electromagnetic flow meter

Release time:2025-04-08

-

What type of flow meter is best suited for measuring flow rate in the petroleum industry?

Release time:2025-04-08

-

The explosion-proof performance of various instruments is extremely important in the chemical production process!

Release time:2025-04-08

Industry News

-

Precise Measurement, Smart Choice: A Comprehensive Analysis of Zhongce Sensing's Pipeline-Type Intelligent Electromagnetic Flowmeter

Release time:2025-09-23

-

Zhongce Sensing Filling Electromagnetic Flowmeter: The Core Tool for Precise Measurement

Release time:2025-09-20

-

Analysis and Application Practices of Insertion Electromagnetic Flowmeters

Release time:2025-09-17

-

Technical Analysis of Slurry-Type Electromagnetic Flowmeters

Release time:2025-09-17

-

Precision measurement, replacing imports: Newly launched filling electromagnetic flowmeters empower the beverage and pharmaceutical industries.

Release time:2025-09-12

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: Parameter, Installation, and Selection Guide

Release time:2025-08-05

-

Zhongce Sensing Electromagnetic Water Meter: The Pioneer of Precise Measurement in the Era of Smart Water Management

Release time:2025-08-05

-

Zhongce Sensing Pipeline Electromagnetic Flowmeter: Precise Measurement, the Reliable Choice for Fluid Flow Applications

Release time:2025-07-29

-

Micro and Miniature Electromagnetic Flow Meters: Small Size, Big Impact—Precision Measurement Empowers High-Precision Industries

Release time:2025-07-24

-

Zhongce Sensing's Miniature Electromagnetic Flowmeter: A Highly Efficient and Precise Choice for Measuring Small Flows

Release time:2025-07-19

-

Zhongce Sensing Insertion Electromagnetic Flowmeter: A Highly Efficient and Convenient Solution for Fluid Measurement

Release time:2025-07-19

-

Henan Zhongce Sensor Electromagnetic Water Meter | IP68 Waterproof + Wireless Remote Transmission—Your First Choice for Smart Water Management and Precise Measurement

Release time:2025-07-16

-

Henan Zhongce Sensor Pipeline Electromagnetic Flowmeter: The Industrial Choice for High-Precision Fluid Measurement

Release time:2025-07-16

-

Micro and Miniature Electromagnetic Flow Meters: The Ideal Tool for Precisely Measuring Tiny Flow Rates

Release time:2025-07-14

-

What are the maintenance methods for electromagnetic flow meters?

Release time:2025-05-08

-

Difference between electromagnetic water meters and electromagnetic flow meters

Release time:2025-05-08

-

Advantages of electromagnetic flow meters

Release time:2025-05-08

-

Internal structure of a magnetic flow meter

Release time:2025-05-08

-

Electromagnetic flow meter principle

Release time:2025-05-08

-

Troubleshooting common malfunctions of electromagnetic flow meters

Release time:2025-05-08